The craft of production: behind the scenes at Inside, a global player in window decoration

In the world of interior design, every detail is crucial, and this is certainly true for curtains. Behind the scenes of the production process of mid- and high-end curtains lies a fascinating combination of precision, craftsmanship, and innovation. Let's take a deeper dive into the world of window decoration and discover what it entails.

-

1. Fabric dynamics

At Inside, each piece of fabric is carefully produced and/or selected based not only on quality but also on factors like how it reacts to temperature changes. Testing our products is an essential part of our production process. This ensures we can always guarantee the quality our customers expect from us. We test for performance and durability properties, as well as lightfastness, colorfastness, and so on.

-

2. Weaving and construction

The production team at Inside pays great attention to the weaving and construction of the fabric. Every pattern and texture is carefully chosen to create not only an aesthetically appealing curtain but also a durable and functional product that will last for years.

-

3. Automated processes

Modern technologies have transformed the curtain production process, and Inside leads the way with advanced automated machines such as our automatic laser cutting table. These machines not only provide a more efficient process but also ensure unparalleled precision and consistency in every detail of the curtain.

-

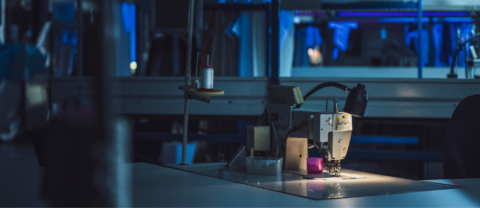

4. Manual finishing

Although Inside utilizes advanced technologies, manual finishing remains an essential part of the production process. Adding handmade details and finishes gives each curtain a unique character and a touch of craftsmanship that cannot be replicated.

-

5. Accuracy and customization

At Inside, each curtain is custom-made with an unparalleled level of accuracy and precision. From the first measurement to the final stitch, every effort is made to ensure each curtain fits perfectly and meets the specific requirements of the customer.

-

6. Packaging and transport

The production team at Inside understands the importance of flawless presentation upon arrival. Each curtain is carefully and meticulously packed with white gloves to prevent stains. Additionally, we select the most suitable packaging for each product type for optimal protection during transport, whether it's to the US, Asia, or elsewhere in the world.

-

7. Quality control

Before a curtain leaves Inside's factory, it undergoes thorough quality control. Every detail is carefully inspected, and each curtain is checked up to three times for finishing and possible fabric defects to ensure that only the highest quality products reach the customers.

-

8. Craftsmanship and pride

At Inside, craftsmanship is more than just a skill; it's a passion shared by every member of the production team. Proud to deliver curtains of unparalleled quality, Inside is a brand driven by a deep commitment to craftsmanship and excellence.

-

In the world of mid- and high-end curtains, the production process at Inside is a story of dedication, precision, and pride. Each curtain tells the story of craftsmanship and excellence, from the first fiber to the moment it adorns a customer's space, wherever that may be in the world. Curious for a behind-the-scenes look at Inside? Click here to watch our video.